Quality precision welding and fabrication services are essential to almost any industry that depends on custom metal parts. Accurately creating a functioning component from a part design often involves joining multiple metal pieces together. This may require extensive precision welding and fabrication processes, either before or after welding.

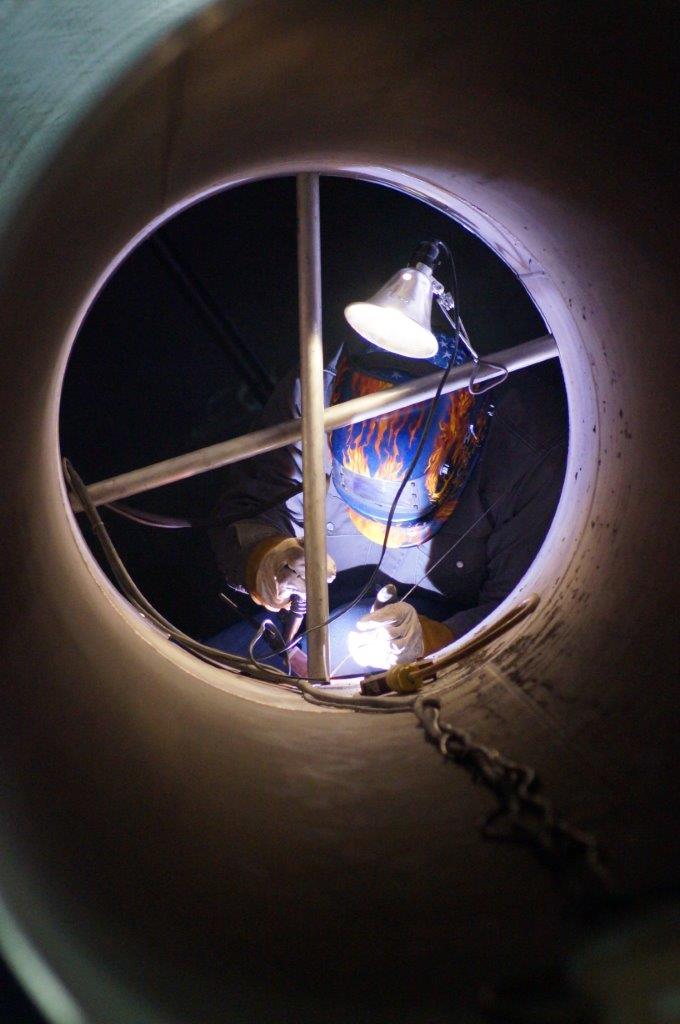

At Precision Welding and Fabrication, we specialize in comprehensive welding and fabrication services for a wide range of steel applications. Our expertise includes working with structural steel, piping, and miscellaneous steel. Together, efficient precision welding and fabrication processes are necessary for accurate and reliable metal manufacturing. The quality of fabrication and welding plays an essential role in ensuring numerous global industries have the metal parts needed to consistently satisfy market demand.

Overview of Welding and Fabrication

Designing and producing metal structures begins with highly skilled welding and fabrication services. Precision welding and fabrication go hand in hand. However, fabrication and welding are also fully distinct processes. Fabrication involves numerous subspecialties, including the following:

- Oxy/Acetylene Waterjet and Plasma

- Plate Bending & Shearing

- MIG (GMAW), TIG (GTAW), Flux Core (GMAW), Sub-Merge Arc (SAW), Stick (SMAW)

- Hole Punching

- Plate Rolling

Welding is a type of joining process for combining metal pieces. It achieves a permanent bond, most often by applying a concentrated blast of heat and pressure to melt a filler-metal compound. The filler-metal quickly conforms to the adjoining metal pieces, fastening them together.

High-quality welds require pre-fabrication to ensure the connecting pieces have suitable mating surfaces for a lasting weld. There are also numerous types of welding processes, each with its own advantages and applications. Different types of welding methods are more suitable for particular metals or joining techniques.

With a skilled welding and fabricating team possessing an in-depth understanding of industry codes, standards, and procedures, our precision welding and fabrication services go beyond the basics. We collaborate closely with our customers, ensuring that we not only identify the appropriate materials and welding techniques but also create effective welds that meet stringent industrial criteria. Metal part designs also depend on the right precision welding and fabrication processes. As mentioned, fabrication is often necessary before a weld, to facilitate a stronger connection. Once welded, parts also often undergo additional fabrication, where the strength of the weld is put to the test.

Highly proficient precision welding and fabrication services form the foundation of high-quality, custom metal parts. Both welding and fabricating processes are more effective when a single provider provides both services fully in-house, allowing them to carefully select and sequence all fabrication and welding procedures for maximum quality, efficiency, and cost-effectiveness.

Industries & Applications of Welding and Fabrication

Together, custom precision welding and fabrication services provide reliable metal components for numerous industries, including the following:

- Construction

- Aerospace

- Pharmaceutical

- Sub-sea

- Food processing

- Oil and Gas

- Natural Gas Pipeline Equipment

- Shipbuilding

- Manufacturing

- Flares

These industries and more depend on custom metal parts meeting stringent tolerance windows and other industry standards. Proper metal fabrication techniques require extensive planning and careful selection from a variety of precision welding and fabricating methods to achieve the manufacturer’s exact design standards.

Welding and Fabrication Product/Service Capabilities

With an effective and flexible management team and a process-oriented approach, we deliver high-efficiency precision welding and fabrication processes that can easily replicate high quantities of standard or custom parts. Depending on the exact technologies and techniques, our metal fabrication and welding specialists can achieve highly consistent part uniformity or match fully custom designs with respect to exact dimensions and other design standards. To ensure that our customers receive their parts when they need them, we have established long-term relationships with third-party service providers, including galvanizers, coating and painting contractors, and material vendors.

Depending on the application, we can use a wide range of raw materials, specifically different steel and various alloys. At Precision Welding and Fabrication, our experience allows us to provide working prototypes before you commit to full production runs.

We also maintain full production run capacities, allowing us to rapidly carry an initial design to completion, with a finished, assembly-ready component with the option of expedited delivery. However sophisticated your metal fabrication and welding services must be, the greater your metal fabrication partner’s skills and experience must also be.

Welding and Fabrication services From Precision Welding and Fabrication

Precision Welding and Fabrication has served as Texas’ premier welding and fabrication shop, providing high-quality, reliable service for over 40 years. With American Welding Society certifications in the structural steel and welding industries, we meet and exceed some of the tightest regulatory standards of our trade. If you’d like to learn more about our capabilities, Contact us or request a quote on any of our in-house precision welding and fabrication services.