At Precision Welding and Fabrication, we specialize in providing high-quality process piping fabrication and process piping installation services. Our expertise covers a wide range of industries and guarantees the safe and efficient flow of liquids, gases, and other materials through strong piping systems. Adhering to strict industry standards like ASME B31.3 and ASME B31.8, we offer comprehensive solutions that meet the unique requirements of each project.

At Precision Welding and Fabrication, we specialize in providing high-quality process piping fabrication and process piping installation services. Our expertise covers a wide range of industries and guarantees the safe and efficient flow of liquids, gases, and other materials through strong piping systems. Adhering to strict industry standards like ASME B31.3 and ASME B31.8, we offer comprehensive solutions that meet the unique requirements of each project.

Overview of ASME Process Piping Standards

The ASME Process Piping Code, specifically ASME B31.3 and ASME B31.8, provides essential guidelines for the design, construction, and maintenance of pressure piping systems. These standards are crucial for guaranteeing safety and reliability across various applications, such as chemical plants, refineries, and cryogenic facilities.

ASME B31.3 applies to process piping systems handling high-pressure fluids, while B31.8 is focused on pipelines transporting gas. These codes outline material requirements, testing procedures, and fabrication practices to meet operational demands. We are committed to following these standards in every project, making sure that each piping system is built for durability and optimal performance.

Precision Welding and Fabrication’s Process Piping Capabilities

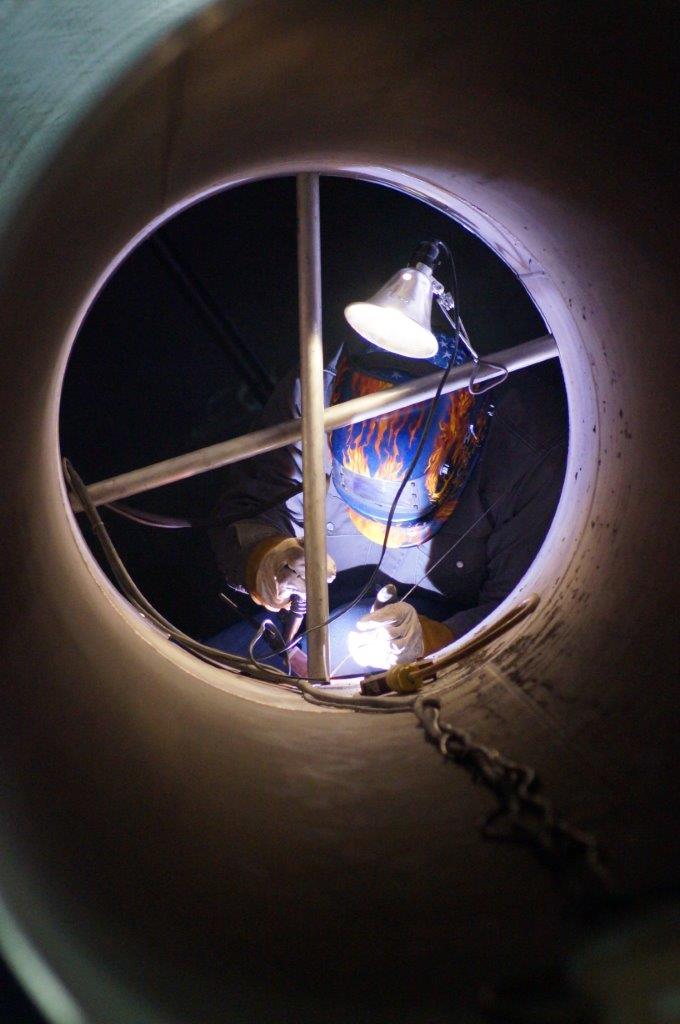

We offer a full spectrum of services related to process piping fabrication and installation. Our skilled team excels in fabricating large-diameter pipes, performing pipe bending and rolling, conducting hydro-testing, and carrying out hydraulic torque bolting. We also use non-destructive testing methods to verify the integrity and safety of each system.

Our services span various materials, including stainless steel, duplex stainless, Inconel, and carbon steel. These materials are selected based on their ability to withstand high pressures, extreme temperatures, and the specific demands of each application. Our extensive experience in working with these materials allows us to provide reliable solutions that comply with ASME standards.

Our process piping and mechanical install services integrate seamlessly into any industrial setting. Our installation teams are trained to follow precise industry standards, making sure that every system is installed with the highest level of accuracy. This includes the assembly of complex piping networks, ensuring proper alignment, and integrating mechanical components to guarantee smooth operation.

Our focus on both process piping and mechanical install means that we deliver a complete, reliable, and efficient solution from start to finish. We prioritize the safe transport of fluids, while making sure the system is optimized for long-term performance.

Industries Served

Precision Welding and Fabrication provides process piping fabrication and process piping installation services to a wide variety of industries. We work with clients in:

- Petroleum Refineries and Gas Production: Guaranteeing the safe transport of critical substances in high-demand environments.

- Food and Beverage Processing: Adhering to sanitary standards while providing efficient piping systems for large-scale operations.

- Cryogenic and Aerospace Facilities: Constructing highly specialized piping systems that operate under extreme conditions.

- Pulp and Paper Processing: Guaranteed smooth operations by delivering reliable, durable piping systems.

- Defense and Space Industries: Providing strong, secure piping solutions for sensitive and high-stakes applications.

Why Choose Precision Welding and Fabrication?

With years of experience in process piping fabrication and process piping installation, we offer the expertise and reliability that industrial clients can depend on. Our skilled team, backed by a solid track record, guarantees that each project adheres to the strict industry codes and standards.

By choosing us for your process piping needs, you can expect a commitment to precision, safety, and efficiency. Contact us today to discuss how we can support your next project and provide specific solutions that meet your specific needs.