Precision Welding and Fabrication specializes in manufacturing ASME pressure vessels built for safety, durability, and compliance with strict industry standards. These vessels are fabricated using high-quality steel materials, including stainless steel, duplex stainless, and 516-70 steel, to meet the demands of industries such as oil and gas, petrochemical, and defense.

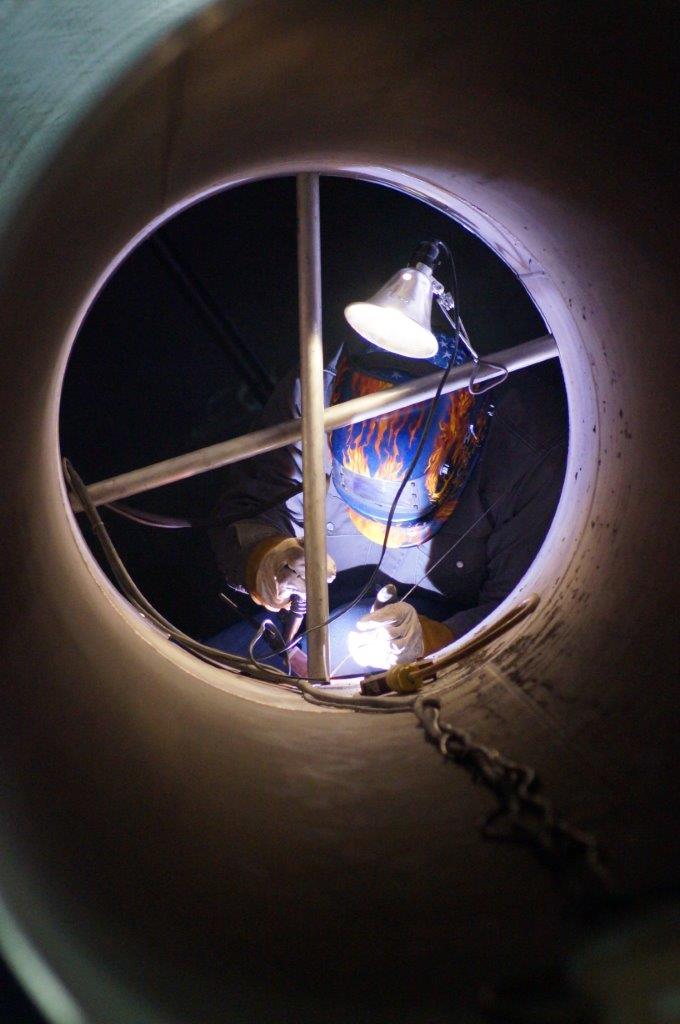

Each ASME pressure vessel is built using approved welding procedures and materials. Fabrication follows the ASME Boiler and Pressure Vessel Code, having structural integrity and long-term performance. The ASME Boiler and Pressure Vessel Code (BPVC) is a set of safety standards developed by the American Society of Mechanical Engineers (ASME) to regulate the design, fabrication, and inspection of boilers and pressure vessels. The code covers material selection, welding procedures, testing requirements, and quality control measures. Compliance with ASME BPVC is mandatory in many regions, having reliability and safety in industrial operations.

Every vessel we create undergoes hydrostatic testing to confirm safety and reliability, and since 1983, our commitment to quality has resulted in a repair rate of less than 1/10 of 1%.

Industries Served

The oil and gas industry relies on ASME pressure vessels for critical processes, including separation, storage, and heat transfer. Separation vessels remove gas, oil, and water from extracted hydrocarbons, ensuring purity and efficiency in downstream processing. Storage tanks hold crude oil, natural gas, and refined products under high pressure, preventing leaks and contamination. Heat exchangers regulate temperatures during refining, optimizing energy use and maintaining process stability.

In the petrochemical sector, ASME pressure vessels support chemical reactions and material transformations essential for producing fuels, plastics, and industrial chemicals. Reactors provide controlled environments for high-pressure chemical reactions. Distillation columns separate chemical components based on boiling points, improving the efficiency of refining and synthesis. Gas scrubbers remove contaminants from gaseous streams, reducing emissions and meeting environmental regulations.

The military and defense industry depends on ASME pressure vessels for mission-critical applications. Hydraulic accumulators store pressurized fluid to support high-performance military machinery, improving response time and operational efficiency. Propellant storage tanks provide safe containment for fuels used in aerospace and missile systems. Decontamination systems hold chemical agents for neutralization, ensuring rapid response to hazardous situations.

ASME pressure vessels also support other industrial applications, including recompression chambers used for controlled pressurization in diving and hyperbaric treatments. Flares safely burn off excess gases in oil and gas operations, preventing dangerous pressure build-ups and reducing environmental impact. These vessels are integral to maintaining safe and efficient operations across a range of industries.

Benefits of Using an ASME Pressure Vessel

Choosing an ASME pressure vessel provides several advantages, ensuring safety, performance, and long service life.

- Regulatory Compliance – Built to ASME Boiler and Pressure Vessel Code, meeting national and international safety standards.

- Structural Integrity – Engineered to withstand extreme pressure and temperature fluctuations.

- Long-Term Reliability – Designed for durability, reducing maintenance and downtime.

- Versatility – Used in diverse industries, including oil and gas, petrochemical, and defense.

- Safety Assurance – Hydrostatic testing and strict quality control measures confirm vessel performance before deployment.

Pressure Tested, Industry Approved–Your ASME Vessel Starts Here

Looking for a reliable partner for ASME pressure vessel fabrication? With decades of experience, commitment to precision, and backed by a series of certifications, we guarantee that we can provide durable and tested solutions. Contact us today to discuss your project requirements and find the right solution for your application. We are ready to provide guidance and a competitive quote. Contact us today, and let’s get started on your ASME pressure vessel needs.